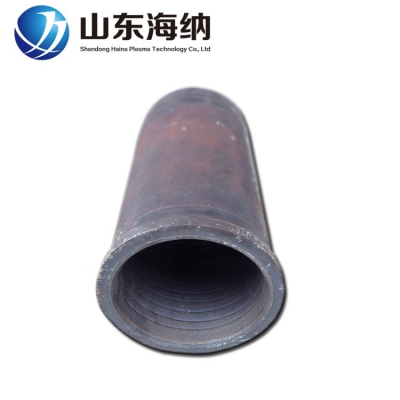

Brief introduction of technology: plasma fine cladding is a fine surface strengthening process, which can strengthen the inner wall of pipe, hole (inner diameter is more than 70mm) or the outer surface of workpiece to increase its wear resistance, corrosion resistance and high temperature oxidation resistance. In this process, the substrate is melted by microbeam plasma arc, and the alloy powder is synchronously fed into the molten pool to form a high-performance cladding layer metallurgically combined with the substrate by convection, homogenization and solidification of the molten pool under the action of the plasma arc. Technical characteristics: the thickness of the cladding layer obtained by adopting the process can be accurately controlled (1-5mm), the thickness is uniform, the dilution rate is low (about 6%), the cladding layer has high purity of components, beautiful molding, metallurgical bonding between the cladding layer and the substrate, and high bonding strength; And because of the small heat input, the heat affected zone of the substrate is small. Ultrasonic and X-ray are used to detect the full coverage of the clad workpiece. The results show that the clad layer is firmly bonded to the substrate, and there are no pinholes, inclusions, cracks and other defects in the clad layer. The analysis results of electron probe and scanning electron microscope show that the alloy elements in the cladding layer are uniformly distributed on the cross section of the cladding layer, and the reinforced carbides in the cladding layer are uniformly distributed. Application conditions: different powder systems can be selected to treat workpieces under severe working conditions such as low stress wear, high temperature wear, impact wear, corrosion, etc. (Fe, Cr)7C3 is the main strengthening phase of the wear-resistant cladding layer, and its hardness reaches HRC68. The wear test is carried out according to ASTM-G65 standard. The wear weight loss of the cladding layer is only 0.056g g. Under the same test conditions, the wear amounts of vermicular cast iron cylinder liner and Swedish Hardox450 wear-resistant steel are 3.1g and 1.8g respectively, and the wear resistance is increased 54 times and 32 times respectively. CrC or WC strengthening phase can also be added as required to meet the requirements of different working conditions. The service life of the high-temperature wear-resistant layer prepared by the process under the working condition of 700 DEG C is 5-15 times of that of stainless steel parts. The corrosion resistance of the prepared corrosion-resistant cladding layer can be better than that of the chromium-plated layer. Pitting corrosion test according to ASTM-G48 standard shows that the corrosion resistance of the cladding layer is 1.2-2 times that of 304 stainless steel. Technical advantages: Compared with laser cladding process, this process has the advantages of single cladding layer thickness, full metallurgical process, no slag inclusion, cladding inner hole of workpiece, etc. Compared with electroplated hard chromium, it has the advantages of no Cr6+ pollution, thick cladding layer, superior wear resistance at high temperature, metallurgical bonding with the substrate, flexible addition of alloy elements as required, etc. Compared with plasma spraying, it has the advantages of thick cladding layer, compact structure, no pores, inclusions and cracks, and firm combination with the substrate. Therefore, the technology can replace the above technology and be applied to the reinforcement of workpieces under severe working conditions such as cylinder liners, oil cylinders, hydraulic support columns, etc.

-

contact number:

0531-86954567

contact number:

0531-86954567

-

-

Reasonable Price

Reasonable Price

-

Quality Assurance

Quality Assurance

-

First-rate Service

First-rate Service

-

Fully Equipped

Fully Equipped

-